FORD

COMPANY PROFILE

Ford Dunton UK is home to Europe’s most technologically advanced Environmental Test Laboratory (ETL) which is used to test Ford’s small and medium cars and light commercial vehicles world-wide in a variety of simulated environments. The ETL has climatic test chambers which can simulate pressure altitudes from 91.4 m (300 ft) below sea level, to 3658 m (12,000 ft) above sea level — from Death Valley in the United States to La Paz, Bolivia. A 3-m (9.8 -ft) diameter fan capable of replicating speeds up to 225 km/h (140 mph) provides airflow in the main wind tunnel. A four-wheel drive dynamometer simulates road speeds up to 250 km/h (155 mph). All chambers can be subjected to controlled temperatures ranging from -40° to +55°C (-40° to +131°F) in conjunction with full humidity control. Two of the test chambers have solar simulation and a “hot rod” system to simulate the effect of the sun’s latent heat on the road surface.

THE SITUATION

Ford were using a legacy MS-DOS RTM package to monitor the test chambers and wanted to replace the software and PC interfaces to be compatible with newer versions of Windows while retaining their significant investment in monitoring hardware located in each chamber.

THE SOLUTION

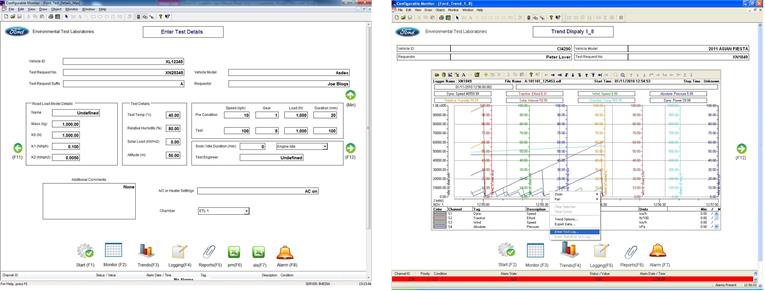

Measuresoft proposed a combination of the 3595 4U Imp USB interface and ScadaPro as a solution to replacing RTM and 3595 4C modules. In addition, Ford and Measuresoft agreed on using Kvaser Leaflight hardware products to provide new CANBus data capture facility from the vehicle under test in each chamber. Measuresoft then prototyped a set of ScadaPro screens to make sure that test engineers would be presented with the same functionality as RTM. The ScadaPro System was installed to acquire data from Solartron Imp data acquisition modules and engine management systems in each vehicle under test. Each shift was provided with extensive training and performed simulated tests. Changeover to the new system was achieved with minimum disruption to the test work schedule.

Ford ETL now have an environmental chamber monitoring system that:

– Is familiar to test engineers and allows them to set up test quickly.

– Provides real-time information for operators to monitor during a test. – Provides real-time and historical trending, which allows an operator zoom into an area of interest and export selected data to a standard Microsoft Excel report format.

BENEFITS

Our solutions offer a range of benefits.

ScadaPro’s real-time measurement capability provides higher accuracy and reliability, ensuring better process results while reducing process uniformity defects.

Problems with sensors can be easily spotted and recorded.

The system can easily be expanded to monitor more laboratory areas.

Leveraging the Microsoft platform provides a solution that is accessible throughout the corporate network.

Operator familiarity with the Windows user interface reduces training costs.